3D Printers VS 3D Printing

🖨 The Great 3D Printing Game

Learn by Playing! 🎮

In the world of technology, learning is not just about memorizing specifications. It’s a journey of discovery 🚀, where we learn how to choose the right 3D printer for each object and make smart decisions!

This game is not just another tech lesson! It’s an experience that turns players into engineers, researchers, and future creators! 🏗

🖨 How to Start – Setting Up the Game

📥 Step 1: Download the PDF files containing the printer and object cards.

🖨 Step 2: Print them on standard A4 paper – no lamination! 📝 Player notes and thoughts on the cards are valuable!

✍ Step 3: The cards are ready, the players are ready… let’s start the game! 🎮

🎮 Game 1: Which Printer is the Best?

The Challenge: Can you pick the best printer for the given object? 🤔

📌 Rules:

👥 Players are divided into teams and receive 3D printer cards.

📜 The game host selects an object card and places it on the table.

🗣 Each team must "sell" their printer, explaining why it is the best choice!

🏆 The team with the most convincing explanation wins the round!

🎯 Objective: Players learn to compare printer features and think like engineers!

💰 Game 2: Would You Buy This Printer?

The Challenge: Can you make the right choice? 🛍

📌 Rules:

📜 Players are divided into teams and each team gets object cards.

🛍 The game host draws a printer card and "sells" it.

🤔 Players must decide if this printer is suitable for their object – and explain why!

🔍 Objective: Players analyze printer specifications and make smart purchasing decisions, just like in the real world!

⚡ Game 3: Match the Right Printer!

The Challenge: Can you find the perfect match? 🎯

📌 Rules:

🎴 All cards (printers & objects) are distributed among the players.

🔄 Players must match the right printer to the correct object.

📢 Each player explains their choice and defends their logic!

💡 Objective: Players think like 3D printing experts, considering materials, print size, technology, and quality!

🏆 Why is this Game So Important?

In this game, players don’t just memorize information – they become engineers and creators! 🚀

👨🔬 They learn to think practically – analyzing data and making informed decisions.

🛠 They take responsibility for choosing the right equipment – just like professionals!

🚀 They develop critical thinking & problem-solving skills – essential for the future of technology.

🔥 Learning Becomes an Adventure!

Project-Based Education is not just a teaching method. It’s the bridge that transforms knowledge into experience! 🛠

Players are not passive listeners. They are the creators of the future! 🌍

✨ Because the engineers of tomorrow start learning today! 🚀

✨ Tomorrow's engineers start with today's students! 🚀

3D Printers

⚠️ Disclaimer ⚠️

🛑 Important Notice! 🛑

The information provided below for each 3D printer is indicative 📌 and has been gathered from various online sources 🌐. Its sole purpose is to be part of this game 🎮.

❌ These are not official technical specifications

❌ This is not a purchasing recommendation

❌ No warranties or guarantees are provided

✅ What You Should Do Before Buying a 3D Printer:

🔎 Check the official specifications from the manufacturer 🏭

📄 Read the detailed information provided by the company 📝

🎯 Make sure the printer meets your needs and requirements ✅

The following details are for the game only and should not influence your purchasing decision! 🚀

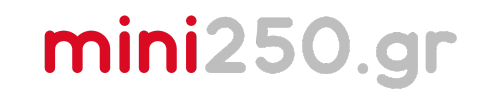

🖨️ Bambu Lab A1 Mini

🖨️ Bambu Lab A1 Mini (English Version)

💠 Type: Desktop 3D Printer

💠 Printing Technology: FDM (likely CoreXY or hybrid system)

💠 Build Volume: ~180 × 180 × 180 mm

💠 Enclosure: Open-frame

💠 Design: Compact and space-saving – perfect for small workspaces and educational use

💠 Extruder: Direct Drive (likely), optimized for flexible materials

💠 Printing Speed: Expected >200 mm/s

💠 Auto Bed Leveling: Likely includes automatic leveling system

💠 Maximum Nozzle Temperature: ~220-250°C (estimated)

💠 Maximum Bed Temperature: ~100°C

💠 Heated Bed: Yes

💠 Assembly Required or Pre-Assembled: Fully assembled

💠 Screen/Control: Likely a color touchscreen, compatible with Bambu Studio

💠 Supported Software: Bambu Studio, Cura, PrusaSlicer

💠 Years on the Market: Expected release in 2024

💠 Filaments: PLA, PETG, TPU, ABS (limited due to open-frame design)

💠 Layer Resolution: 0.05 - 0.3 mm (estimated)

💠 Price: ~€300-500 (expected)

✅ Advantages

✔️ Compact and perfect for small spaces or educational use 🏠🎓

✔️ More affordable entry into Bambu Lab’s ecosystem 💰

✔️ Possible AI-based error detection 📡

✔️ Faster speeds than typical small 3D printers ⚡

❌ Disadvantages

❌ Limited build volume

❌ Open-frame design – limited ABS support

❌ Final specs are not fully confirmed yet

🔥 Special Power

💥 A small yet fast and smart printer – perfect for beginners and educational purposes! 🚀

🖨️ Bambu Lab A1

🖨️ Bambu Lab A1 (English Version)

💠 Type: Desktop 3D Printer

💠 Printing Technology: FDM (likely CoreXY)

💠 Build Volume: ~220–256 mm per side (not officially confirmed)

💠 Enclosure: Semi-enclosed or optional full enclosure

💠 Frame/Design: Larger than A1 Mini, possibly with an enclosure option

💠 Extruder: Direct Drive, optimized for flexible and technical filaments

💠 Auto Bed Leveling: Expected automatic system (possibly lidar-based like X1/P1 series)

💠 Maximum Nozzle Temperature: ~250-300°C (estimated)

💠 Maximum Bed Temperature: ~100°C

💠 Heated Bed: Yes

💠 Assembly Required or Pre-Assembled: Fully assembled

💠 Screen/Control: Color touchscreen, likely cloud connectivity

💠 Supported Software: Bambu Studio, Cura, PrusaSlicer

💠 Years on the Market: Expected release in 2024

💠 Filaments: PLA, PETG, TPU, ABS/ASA, possibly Nylon & Carbon-reinforced

💠 Layer Resolution: 0.05 - 0.3 mm (estimated)

💠 Price: ~€500-800 (expected)

✅ Advantages

✔️ Larger than A1 Mini but more affordable than premium P1/X1 series 📏

✔️ High-speed printing ⚡

✔️ Likely compatible with AMS (Automatic Material System) for multi-color and multi-material 🎨

✔️ Enclosed or semi-enclosed design – better support for technical materials 🏗️

✔️ Direct Drive extruder for TPU and flexible filaments 🛠️

❌ Disadvantages

❌ Official specs not fully confirmed yet

❌ If not fully enclosed, may have limitations with ABS/Nylon

❌ Price and availability still uncertain

🔥 Special Power

💥 A well-balanced printer that bridges the gap between entry-level and premium models – fast, reliable, and versatile! 🚀

🖨️ RepRap Darwin (2007)

🖨️ RepRap Darwin (2007) (English Version)

💠 Type: DIY 3D Printer (first-generation RepRap)

💠 Printing Technology: FDM (Fused Deposition Modeling)

💠 Build Volume: ~200 × 200 × 200 mm (in improved versions)

💠 Design: Moving X-Y axis with chains or belts, Z-axis adjusted with lead screws

💠 Frame: Combination of threaded rods and printed parts

💠 Auto Bed Leveling: No

💠 Maximum Nozzle Temperature: ~240°C (depending on hotend)

💠 Maximum Bed Temperature: No heated bed in original version

💠 Heated Bed: No (original model)

💠 Assembly Required or Pre-Assembled: 100% DIY – required full assembly and part printing

💠 Supported Software: Custom firmware, based on early RepRap software

💠 Years on the Market: Since 2007 (no longer in production)

💠 Filaments: PLA, ABS (with upgrades), and other basic materials

💠 Layer Resolution: ~0.2 - 0.5 mm

💠 Price: No longer sold – component cost was ~€300-500 at the time

✅ Advantages

✔️ The first DIY 3D printer – laid the foundation for the open-source community 🏗️

✔️ Self-replicating – could print its own parts 🔄

✔️ Inspired hundreds of open-source 3D printers 🛠️

✔️ Low cost for its time 💰

❌ Disadvantages

❌ Unstable frame – not as rigid as modern printers 🏗️

❌ No heated bed – difficult to print ABS and other materials 🔥

❌ Slow and low accuracy compared to modern models 🐢

❌ 100% DIY – required extensive assembly and tuning 🔩

🔥 Special Power

💥 The printer that started the DIY 3D printing revolution – the ultimate historical printer! 🚀

🖨️ RepRap Mendel (2009)

🖨️ RepRap Mendel (2009) (English Version)

💠 Type: DIY Desktop 3D Printer (Second-generation RepRap)

💠 Printing Technology: FDM (Fused Deposition Modeling)

💠 Build Volume: ~200 × 200 × 140 mm (original version, larger in variations)

💠 Design: Pyramid-like triangular frame for improved stability over Darwin

💠 Frame: Combination of threaded rods and printed parts

💠 Auto Bed Leveling: No (original version)

💠 Maximum Nozzle Temperature: ~240°C (depends on hotend)

💠 Maximum Bed Temperature: ~110°C (if heated bed is added)

💠 Heated Bed: No (original version, but can be upgraded)

💠 Assembly Required or Pre-Assembled: 100% DIY – requires full assembly and part printing

💠 Supported Software: Custom firmware, based on early RepRap software

💠 Years on the Market: Since 2009 (no longer in production)

💠 Filaments: PLA, ABS (with heated bed), PETG, and other basic materials

💠 Layer Resolution: ~0.1 - 0.4 mm

💠 Price: No longer sold – component cost was ~€300-600

✅ Advantages

✔️ Improved design over Darwin – more stability and better print quality 🏗️

✔️ Open-source and easy to upgrade – led to MendelMax and Prusa Mendel 🛠️

✔️ Self-replicating – could print its own plastic components 🔄

✔️ Set the foundation for modern DIY 3D printers 🎯

❌ Disadvantages

❌ Manual calibration required – no auto bed leveling 🔩

❌ Slower and less rigid than modern printers 🐢

❌ Complex assembly – required DIY and 3D printing knowledge 🏗️

❌ No heated bed in the original version – limited ABS support 🔥

🔥 Special Power

💥 The printer that shaped the future of open-source DIY 3D printing – the foundation for popular models like Prusa! 🚀

🖨️ Prusa Mendel (2010-2011)

🖨️ Prusa Mendel (2010-2011) (English Version)

💠 Type: DIY Desktop 3D Printer

💠 Printing Technology: FDM (Fused Deposition Modeling)

💠 Build Volume: ~200 × 200 × 100–140 mm (depending on version)

💠 Design: Similar to RepRap Mendel but simplified – fewer parts, lower cost

💠 Frame: Combination of threaded rods and printed parts

💠 Extruder: Direct Drive or Bowden (depending on the build)

💠 Auto Bed Leveling: No (original version)

💠 Maximum Nozzle Temperature: ~240°C (depends on hotend)

💠 Maximum Bed Temperature: ~110°C (if heated bed is added)

💠 Heated Bed: No (original version, but upgradeable)

💠 Assembly Required or Pre-Assembled: 100% DIY – requires full assembly and part printing

💠 Supported Software: Marlin (in later versions)

💠 Years on the Market: 2010-2011 (no longer in production)

💠 Filaments: PLA, ABS (with heated bed), PETG, and other basic materials

💠 Layer Resolution: ~0.1 - 0.4 mm

💠 Price: No longer sold – component cost was ~€300-500

✅ Advantages

✔️ Simpler and more affordable than the classic Mendel 🛠️

✔️ A foundation for many DIYers – easy to build and budget-friendly 💰

✔️ Open-source design – laid the groundwork for modern Prusa printers 🎯

✔️ Easily upgradeable – could be improved with a heated bed and better extruder 🔄

❌ Disadvantages

❌ Manual bed leveling required – no auto bed leveling 🔩

❌ Slower and less rigid than modern Prusa printers 🏗️

❌ DIY assembly – required 3D printed parts and manual tuning 🏗️

🔥 Special Power

💥 The printer that made DIY 3D printing easier and more accessible – the foundation of the modern Prusa series! 🚀

🖨️ Voron 2.4

🖨️ Voron 2.4 (English Version)

💠 Type: DIY Desktop 3D Printer

💠 Printing Technology: FDM, CoreXY

💠 Build Volume: 250 × 250 × 250 mm, 300 × 300 × 300 mm, 350 × 350 × 350 mm (or custom)

💠 Enclosure: Fully enclosed

💠 Design: Metal frame (extrusions) with acrylic or PC panels

💠 Motion System: CoreXY with "gantry leveling" on the Z-axis (multiple leadscrews and belts)

💠 Extruder: Direct Drive (Afterburner or Stealthburner)

💠 Auto Bed Leveling: Supports automatic tramming via multiple Z motors

💠 Maximum Nozzle Temperature: ~300°C

💠 Maximum Bed Temperature: ~120°C

💠 Heated Bed: Yes

💠 Assembly Required or Pre-Assembled: 100% DIY – requires full assembly

💠 Supported Software: Klipper (requires Raspberry Pi)

💠 Years on the Market: Since ~2020

💠 Filaments: PLA, PETG, ABS, ASA, Nylon, PC, PA-CF, and more

💠 Layer Resolution: 0.05 - 0.3 mm

💠 Price: ~€1,200-2,000 (depends on components and upgrades)

✅ Advantages

✔️ The "flagship" Voron – maximum rigidity and stability 🎯

✔️ CoreXY with ultra-high speeds and accelerations ⚡

✔️ Fully enclosed – perfect for technical materials like ABS, Nylon, and PC 🔥

✔️ Gantry leveling on the Z-axis – perfect automatic tramming 🛠️

✔️ Open-source with massive community support 🏗️

❌ Disadvantages

❌ 100% DIY assembly – requires attention and experience 🔩

❌ High cost, especially for large builds

❌ More complex tuning compared to more "ready-to-go" printers

🔥 Special Power

💥 The ultimate Voron – for those who want maximum performance, precision, and reliability! 🚀

🖨️ Creality Ender-3 V2

🖨️ Creality Ender-3 V2

💠 Type: Desktop 3D Printer

💠 Printing Technology: FDM (Fused Deposition Modeling)

💠 Build Volume: 220 x 220 x 250 mm

💠 Enclosure: Open-frame

💠 Number of Extruders: 1

💠 Number of Colors: 1 (single-color printing)

💠 Maximum Nozzle Temperature: 255°C

💠 Maximum Bed Temperature: ~100°C

💠 Assembly Required or Pre-Assembled: Requires partial assembly

💠 Supported Software: Creality Slicer, Cura, Simplify3D, PrusaSlicer

💠 Years on the Market: Released in 2020

💠 Filaments: PLA, PETG, TPU, ABS (with proper enclosure)

💠 Layer Resolution: 0.1 - 0.4 mm

💠 Price: ~€180-250

✅ Advantages

✔️ Excellent price-to-performance ratio

✔️ Quiet operation thanks to 32-bit silent motherboard

✔️ Heated glass bed (Carborundum glass) for better adhesion

✔️ User-friendly, great for beginners

✔️ Improved belt tensioner for higher precision

❌ Disadvantages

❌ Manual bed leveling

❌ Open frame – not ideal for ABS printing

❌ Requires assembly (though relatively easy)

🔥 Special Power

💥 One of the most popular and reliable budget 3D printers, perfect for beginners and makers who love upgrades! 🚀

🖨️ Creality Ender-3 S1

🖨️ Creality Ender-3 S1

💠 Type: Desktop 3D Printer

💠 Printing Technology: FDM (Fused Deposition Modeling)

💠 Build Volume: 220 x 220 x 270 mm

💠 Enclosure: Open-frame

💠 Number of Extruders: 1

💠 Number of Colors: 1 (single-color printing)

💠 Maximum Nozzle Temperature: 260°C

💠 Maximum Bed Temperature: ~100°C

💠 Assembly Required or Pre-Assembled: Requires partial assembly

💠 Supported Software: Creality Slicer, Cura, Simplify3D, PrusaSlicer

💠 Years on the Market: Released in 2021

💠 Filaments: PLA, PETG, TPU, ABS

💠 Layer Resolution: 0.1 - 0.4 mm

💠 Price: ~€280-350

✅ Advantages

✔️ Direct Drive "Sprite" extruder – better handling of flexible filaments (TPU)

✔️ Automatic bed leveling (CR Touch) – less hassle with bed adjustments

✔️ Removable magnetic PC (polycarbonate) bed for easy print removal

✔️ Upgraded components compared to previous Ender-3 models

✔️ Quiet operation thanks to a 32-bit silent motherboard

❌ Disadvantages

❌ Open frame – not ideal for ABS printing

❌ Requires assembly (though easier than other models)

❌ Slightly higher price compared to Ender-3 V2

🔥 Special Power

💥 Direct Drive Extruder & Auto-Leveling Combo! 🚀

A fantastic all-around printer for those who want easy setup and flexibility, especially for printing flexible materials! 🎯

Creality CR-10

💠 Type: Desktop 3D Printer

💠 Printing Technology: FDM (Fused Deposition Modeling)

💠 Build Volume: 300 x 300 x 400 mm (larger than Ender-3)

💠 Enclosure: Open-frame

💠 Number of Extruders: 1

💠 Number of Colors: 1 (single-color printing)

💠 Maximum Nozzle Temperature: 260°C

💠 Maximum Bed Temperature: ~100°C

💠 Assembly Required or Pre-Assembled: Requires partial assembly

💠 Supported Software: Creality Slicer, Cura, Simplify3D, PrusaSlicer

💠 Years on the Market: Released in 2017

💠 Filaments: PLA, PETG, TPU, ABS

💠 Layer Resolution: 0.1 - 0.4 mm

💠 Price: ~€300-400

✅ Advantages

✔️ Large build volume – perfect for big projects 🎭

✔️ Sturdy aluminum frame 💪

✔️ Easy to upgrade with auto-leveling, better extruder, etc. 🛠️

✔️ Separate control box for better cooling and stability 🔥

❌ Disadvantages

❌ Manual bed leveling – requires time for calibration

❌ Open-frame design makes ABS printing more challenging

❌ Larger size requires more workspace

🔥 Special Power

💥 Ideal for makers who want to print LARGE objects without limitations! 🏗️🚀

🖨️ Creality CR-10 S Pro V2

🖨️ Creality CR-10 S Pro V2

💠 Type: Desktop 3D Printer

💠 Printing Technology: FDM (Fused Deposition Modeling)

💠 Build Volume: 300 x 300 x 400 mm

💠 Enclosure: Open-frame

💠 Number of Extruders: 1

💠 Number of Colors: 1 (single-color printing)

💠 Auto Bed Leveling: Yes, with BL Touch

💠 Extruder: Dual-gear metal extruder

💠 Maximum Nozzle Temperature: 260°C

💠 Maximum Bed Temperature: ~100°C

💠 Heated Bed: Ultrabase-type (glass/ceramic coating)

💠 Assembly Required or Pre-Assembled: Requires partial assembly

💠 Supported Software: Creality Slicer, Cura, Simplify3D, PrusaSlicer

💠 Years on the Market: Released in 2019

💠 Filaments: PLA, PETG, TPU, ABS, and more

💠 Layer Resolution: 0.1 - 0.4 mm

💠 Price: ~€400-550

✅ Advantages

✔️ Large build volume for big projects 🎭

✔️ Auto bed leveling (BL Touch) for easy calibration 🛠️

✔️ Sturdy construction with high-quality components 💪

✔️ Quiet operation due to the 32-bit silent motherboard 🔇

❌ Disadvantages

❌ Larger size requires more workspace

❌ Open-frame design – not ideal for ABS without an enclosure

❌ Higher cost compared to the standard CR-10

🔥 Special Power

💥 A professional-grade printer with auto-leveling and robust build – perfect for large and precise prints! 🚀

🖨️ Creality Ender-5 Pro

🖨️ Creality Ender-5 Pro (English Version)

💠 Type: Desktop 3D Printer

💠 Printing Technology: FDM (Fused Deposition Modeling)

💠 Build Volume: 220 x 220 x 300 mm

💠 Design: Cube (Box frame) – bed moves vertically on the Z-axis

💠 Enclosure: Open-frame

💠 Number of Extruders: 1

💠 Number of Colors: 1 (single-color printing)

💠 Extruder: Upgraded metal extruder (Mk8)

💠 Maximum Nozzle Temperature: 260°C

💠 Maximum Bed Temperature: ~100°C

💠 Heated Bed: Magnetic, removable

💠 Assembly Required or Pre-Assembled: Requires partial assembly

💠 Mainboard: Silent mainboard with Marlin firmware

💠 Supported Software: Creality Slicer, Cura, Simplify3D, PrusaSlicer

💠 Years on the Market: Released in 2019

💠 Filaments: PLA, PETG, TPU, ABS (with proper conditions)

💠 Layer Resolution: 0.1 - 0.4 mm

💠 Price: ~€300-400

✅ Advantages

✔️ More stable design compared to classic Ender models due to box frame 🏗️

✔️ Ideal for higher printing speeds 🚀

✔️ Easy to assemble and upgrade 🛠️

✔️ Upgraded extruder for better filament feeding 💡

❌ Disadvantages

❌ Manual bed leveling required

❌ Open-frame design – not ideal for ABS without an enclosure

❌ Vertical bed movement may cause slight instability

🔥 Special Power

💥 One of the most stable and fast Ender-series printers – perfect for makers who want speed and precision! 🏎️🔥

🖨️ Creality CR-30 (PrintMill)

🖨️ Creality CR-30 (PrintMill) (English Version)

💠 Type: Desktop 3D Printer with moving conveyor belt

💠 Printing Technology: FDM, with inclined Z-axis and belt (Infinite Z)

💠 Build Volume: 200 x 170 x “infinite” (theoretically, due to moving belt)

💠 Enclosure: Open-frame

💠 Number of Extruders: 1

💠 Number of Colors: 1 (single-color printing)

💠 Extruder: Direct Drive

💠 Maximum Nozzle Temperature: 240-250°C

💠 Maximum Bed Temperature: ~100°C

💠 Heated Bed: Moving nylon conveyor belt with special coating

💠 Assembly Required or Pre-Assembled: Pre-assembled

💠 Supported Software: Special edition Cura or IdeaMaker

💠 Years on the Market: Released in 2020

💠 Filaments: PLA, PETG, TPU (upgradable for ABS)

💠 Layer Resolution: 0.1 - 0.4 mm

💠 Price: ~€900-1,200

✅ Advantages

✔️ Continuous printing capability (mass production) ♾️

✔️ Ability to print extra-long objects 🏗️

✔️ Direct drive extruder for better filament feeding

✔️ Pre-assembled – ready to use

❌ Disadvantages

❌ Requires special slicing setup – only works with a modified Cura or IdeaMaker

❌ Limited print height and width (only the length is "infinite")

❌ Higher cost compared to traditional 3D printers

🔥 Special Power

💥 Perfect for those who want to print extra-long objects or produce small prints in continuous flow! 🚀♾️

🖨️ Creality Sermoon V1

🖨️ Creality Sermoon V1 (English Version)

💠 Type: Desktop 3D Printer

💠 Printing Technology: FDM (Fused Deposition Modeling)

💠 Build Volume: 175 x 175 x 165 mm

💠 Design: Fully enclosed – perfect for educational or office use

💠 Enclosure: Closed-frame

💠 Number of Extruders: 1

💠 Number of Colors: 1 (single-color printing)

💠 Extruder: Direct Drive (Sprite extruder)

💠 Auto Bed Leveling: Yes, with CR Touch

💠 Maximum Nozzle Temperature: 250-260°C

💠 Maximum Bed Temperature: ~100°C

💠 Heated Bed: Yes

💠 Assembly Required or Pre-Assembled: Fully assembled (Plug & Play)

💠 Supported Software: Creality Slicer, Cura, Simplify3D, PrusaSlicer

💠 Years on the Market: Released in 2021

💠 Filaments: PLA, PETG, TPU, ABS (with limitations)

💠 Layer Resolution: 0.1 - 0.4 mm

💠 Price: ~€350-450

✅ Advantages

✔️ Fully enclosed chamber for safer and more stable prints 🔒

✔️ Very quiet operation – perfect for schools and offices 🤫

✔️ Comes fully assembled, ready to print (Plug & Play) 🎛️

✔️ Auto bed leveling (CR Touch) for easy calibration 🛠️

❌ Disadvantages

❌ Smaller build volume compared to other printers

❌ Limited ABS support due to temperature constraints

❌ Slightly higher price compared to other beginner 3D printers

🔥 Special Power

💥 The ultimate 3D printer for beginners and education – simple, safe, and ready to print right out of the box! 🏫✨

🖨️ Creality Halot-One

🖨️ Creality Halot-One (English Version)

💠 Type: Desktop Resin 3D Printer

💠 Printing Technology: LCD Resin (SLA/DLP-like)

💠 Build Volume: 127 x 80 x 160 mm

💠 Light Source: 120W LED Matrix

💠 Screen: 6.08" 2K LCD for resin curing

💠 Resolution: 2560 x 1620 pixels

💠 Layer Accuracy: 0.01 - 0.2 mm

💠 Enclosure: Closed-frame

💠 Assembly Required or Pre-Assembled: Ready to use

💠 Supported Software: Halot Box, ChiTuBox, Lychee Slicer

💠 Years on the Market: Released in 2021

💠 Filaments: UV Resin (Photopolymer Resin)

💠 Price: ~€200-300

✅ Advantages

✔️ Affordable price for a resin printer 💰

✔️ High precision and fine details 🎨

✔️ Closed chamber for better safety and reduced odors 🔒

✔️ Relatively easy to use for SLA beginners 🛠️

❌ Disadvantages

❌ Small build volume

❌ Resin handling requires caution and good ventilation ☢️

❌ Prints require post-processing (washing, UV curing)

🔥 Special Power

💥 A budget-friendly and precise resin printer – perfect for modeling, jewelry, and ultra-detailed prints! ✨

🖨️ Creality LD-002H

🖨️ Creality LD-002H (English Version)

💠 Type: Desktop Resin 3D Printer

💠 Printing Technology: LCD Resin

💠 Build Volume: 130 x 82 x 160 mm

💠 Light Source: UV LED

💠 Screen: 6.0" 2K LCD

💠 Resolution: 2560 x 1620 pixels

💠 Layer Accuracy: 0.01 - 0.2 mm

💠 Air Purification System: Built-in activated carbon filter

💠 Enclosure: Closed-frame

💠 Assembly Required or Pre-Assembled: Ready to use

💠 Supported Software: ChiTuBox, Lychee Slicer

💠 Years on the Market: Released in 2021

💠 Filaments: UV Resin (Photopolymer Resin)

💠 Price: ~€250-350

✅ Advantages

✔️ High resolution and excellent print quality 🎨

✔️ Sturdy and stable construction 🏗️

✔️ Built-in activated carbon filter to reduce odors 🔬

✔️ Ideal for detailed prototypes, figurines, and jewelry 💍

❌ Disadvantages

❌ Small build volume

❌ Resin handling requires caution and proper ventilation ☢️

❌ Requires post-processing (washing, UV curing)

🔥 Special Power

💥 A powerful and precise resin printer with an activated carbon filter for a more comfortable printing experience! 🔥

🖨️ Creality Ender-2 Pro (Portable Mini Printer)

🖨️ Creality Ender-2 Pro (Portable Mini Printer) (English Version)

💠 Type: Desktop Portable 3D Printer

💠 Printing Technology: FDM (Fused Deposition Modeling)

💠 Build Volume: 165 x 165 x 180 mm

💠 Design: Cantilever-style, ultra-lightweight and portable

💠 Enclosure: Open-frame

💠 Number of Extruders: 1

💠 Number of Colors: 1 (single-color printing)

💠 Heated Bed: Yes

💠 Screen: LCD with rotary knob

💠 Maximum Nozzle Temperature: 240-250°C

💠 Maximum Bed Temperature: ~100°C

💠 Assembly Required or Pre-Assembled: Simple assembly (ready in minutes)

💠 Supported Software: Creality Slicer, Cura, Simplify3D, PrusaSlicer

💠 Years on the Market: Released in 2021

💠 Filaments: PLA, PETG, TPU (with proper settings)

💠 Layer Resolution: 0.1 - 0.4 mm

💠 Price: ~€150-200

✅ Advantages

✔️ Very affordable – perfect for beginners 💰

✔️ Ultra-lightweight and portable – easy to carry 🎒

✔️ Quick and easy assembly – ready to use in minutes 🛠️

✔️ Good print quality for its size 🎨

❌ Disadvantages

❌ Small build volume

❌ Manual bed leveling required

❌ Limited compatibility with more demanding materials like ABS

🔥 Special Power

💥 The perfect mini 3D printer for travel, education, and beginners – simple, lightweight, and budget-friendly! ✈️🎒

🖨️ Original Prusa i3 MK3S+

🖨️ Original Prusa i3 MK3S+ (English Version)

💠 Type: Desktop 3D Printer

💠 Printing Technology: FDM (Fused Deposition Modeling)

💠 Build Volume: 250 × 210 × 210 mm

💠 Enclosure: Open-frame

💠 Number of Extruders: 1

💠 Number of Colors: 1 (single-color printing, upgradeable to multi-color with MMU)

💠 Auto Bed Leveling: Dynamic system with SuperPINDA sensor for automatic bed mapping

💠 Motherboard: 8-bit or 32-bit (depending on version), with advanced safety and detection features

💠 Filament Sensor: Yes, detects when filament runs out or gets clogged

💠 Maximum Nozzle Temperature: 280°C

💠 Maximum Bed Temperature: ~120°C

💠 Heated Bed: Flexible, removable spring steel sheet

💠 Assembly Required or Pre-Assembled: Available as a kit or fully assembled

💠 Supported Software: PrusaSlicer, Cura, Simplify3D

💠 Years on the Market: Released in 2020

💠 Filaments: PLA, PETG, ABS, ASA, Flex (TPU), Nylon, and more

💠 Layer Resolution: 0.05 - 0.35 mm

💠 Price: ~€800-1,000

✅ Advantages

✔️ Reliable and outstanding print quality 🏆

✔️ Power Panic function – resumes printing after power loss ⚡

✔️ Extremely quiet operation thanks to Trinamic drivers 🔇

✔️ Strong community support and frequent upgrades 📚

✔️ Flexible removable print bed for easy print removal 🛠️

❌ Disadvantages

❌ Higher cost compared to budget 3D printers

❌ Open-frame design – not ideal for ABS without an enclosure

❌ Assembly time required for DIY (kit) version

🔥 Special Power

💥 The ultimate 3D printer for hobbyists and small workshops – stable, high-quality, and backed by an amazing community! 🚀

🖨️ Original Prusa MINI+

🖨️ Original Prusa MINI+ (English Version)

💠 Type: Desktop 3D Printer

💠 Printing Technology: FDM (Fused Deposition Modeling)

💠 Build Volume: 180 × 180 × 180 mm

💠 Design: Compact size, ideal for small spaces or portability

💠 Enclosure: Open-frame

💠 Number of Extruders: 1

💠 Number of Colors: 1 (single-color printing, upgradeable to multi-color with MMU)

💠 Auto Bed Leveling: SuperPINDA sensor for automatic bed mapping

💠 Motherboard: 32-bit Buddy board with silent Trinamic drivers

💠 Filament Sensor: Optional in some kits

💠 Maximum Nozzle Temperature: 280°C

💠 Maximum Bed Temperature: ~100°C

💠 Heated Bed: Removable, flexible spring steel sheet

💠 Assembly Required or Pre-Assembled: Available as a kit or fully assembled

💠 Screen: Color LCD

💠 Supported Software: PrusaSlicer, Cura, Simplify3D

💠 Years on the Market: Released in 2020

💠 Filaments: PLA, PETG, ABS/ASA (limited due to open-frame), TPU, and more

💠 Layer Resolution: 0.05 - 0.35 mm

💠 Price: ~€400-500

✅ Advantages

✔️ Affordable price for a Prusa printer 💰

✔️ Perfect for beginners – easy to use and highly reliable 🛠️

✔️ Excellent print quality despite its small size 🎨

✔️ Great choice for small workshops, schools, and as a second printer 🏫

❌ Disadvantages

❌ Smaller build volume compared to other Prusa models

❌ Open-frame design – not ideal for ABS printing

❌ Filament sensor is not included in all kits

🔥 Special Power

💥 A small but powerful printer – perfect for beginners and professionals looking for a compact, reliable 3D printer! 🚀

🖨️ Original Prusa i3 MK4

🖨️ Original Prusa i3 MK4 (English Version)

💠 Type: Desktop 3D Printer

💠 Printing Technology: FDM (Fused Deposition Modeling)

💠 Build Volume: 250 × 210 × 220 mm (slightly increased height compared to MK3S+)

💠 Enclosure: Open-frame

💠 Number of Extruders: 1

💠 Number of Colors: 1 (single-color printing, upgradeable with MMU for multi-color)

💠 Extruder: Nextruder – Redesigned direct drive extruder with improved cooling and precise flow control

💠 Auto Bed Leveling: Upgraded high-accuracy Load Cell sensor

💠 Motherboard: 32-bit with improved firmware, Wi-Fi or Ethernet connectivity (depending on version)

💠 Filament Sensor: Yes, upgraded for better accuracy

💠 Maximum Nozzle Temperature: 300°C

💠 Maximum Bed Temperature: ~120°C

💠 Heated Bed: Removable metal surface with multiple options (smooth, textured, etc.)

💠 Assembly Required or Pre-Assembled: Available as a kit or fully assembled

💠 Supported Software: PrusaSlicer, Cura, Simplify3D

💠 Years on the Market: Released in 2023-2024

💠 Filaments: PLA, PETG, ABS/ASA, TPU, Nylon, and more

💠 Layer Resolution: 0.05 - 0.35 mm

💠 Price: ~€1,000-1,200

✅ Advantages

✔️ Even better precision and ease of use compared to MK3S+ 🎯

✔️ Extremely quiet operation thanks to new motherboard and Trinamic drivers 🔇

✔️ Remote control via Wi-Fi or Ethernet 📡

✔️ Superior print quality “out of the box” 🎨

✔️ Improved filament detection and automatic bed leveling 🛠️

❌ Disadvantages

❌ Higher cost compared to MK3S+

❌ No enclosure – limited ABS support without upgrades

❌ Possible wait times due to high demand

🔥 Special Power

💥 The next generation of the Prusa i3 series – even smarter, more precise, and ready to print masterpieces! 🚀

🖨️ Original Prusa SL1S

🖨️ Original Prusa SL1S (English Version)

💠 Type: Desktop Resin 3D Printer

💠 Printing Technology: MSLA (Masked Stereolithography)

💠 Build Volume: 127 × 80 × 150 mm (varies by version)

💠 Enclosure: Closed-frame

💠 UV Screen: 5.96" or 6.25" (depending on version), high-resolution LCD

💠 Light Source: Powerful UV LED array for fast curing

💠 Resolution: 2560 × 1620 pixels (2K+)

💠 Printing Speed: Much faster compared to other SLA/MSLA printers

💠 Air Filtration System: Not included (good ventilation recommended)

💠 Assembly Required or Pre-Assembled: Ready to use

💠 Screen: Color touchscreen

💠 Supported Software: PrusaSlicer (optimized for resin printing)

💠 Years on the Market: Released in 2021

💠 Compatible Resins: Standard, Tough, Flexible, Dental, etc. (Prusa and third-party resins supported)

💠 Price: ~€1,600-1,900

✅ Advantages

✔️ Exceptional quality and fine details – ideal for modeling, jewelry, and dental applications 🎨💎

✔️ Faster curing time compared to other SLA printers ⚡

✔️ Sturdy and stable construction 🏗️

✔️ Supported by the Prusa ecosystem and strong community 🛠️

✔️ Compatible with Prusa’s CW1 post-curing system 🔬

❌ Disadvantages

❌ Higher cost compared to other MSLA printers

❌ Requires good ventilation and careful resin handling ☢️

❌ Limited build volume

🔥 Special Power

💥 The ultimate resin printer for professional-level detail and speed – perfect for modelers, jewelers, and dentists! 🦷💎✨

🖨️ Original Prusa XL

🖨️ Original Prusa XL (Large-Scale) (English Version)

💠 Type: Desktop/Industrial 3D Printer

💠 Printing Technology: FDM (Fused Deposition Modeling)

💠 Build Volume: 360 × 360 × 360 mm (or larger, depending on configuration)

💠 Enclosure: Closed or semi-closed (depending on final version)

💠 Tool Changer (Optional): Yes, with multi-tool/multi-nozzle capability

💠 Number of Extruders: 1-5 (depending on configuration)

💠 Number of Colors: Multi-material capability with tool changer

💠 Extruder: Next-generation Nextruder with improved thermal management and sensors

💠 Auto Bed Leveling: High-precision system with sensors on each tool

💠 Motherboard: 32-bit, networking capabilities (Wi-Fi, Ethernet), large color touchscreen

💠 Filament Sensor: Yes, upgraded for higher accuracy

💠 Maximum Nozzle Temperature: 300°C

💠 Maximum Bed Temperature: ~120°C

💠 Heated Bed: Modular metal surface with multiple options (smooth, textured, etc.)

💠 Assembly Required or Pre-Assembled: Available as a kit or fully assembled

💠 Supported Software: PrusaSlicer

💠 Years on the Market: 2023+ (gradually released via pre-orders)

💠 Filaments: PLA, PETG, ABS, ASA, TPU, Nylon, and more

💠 Layer Resolution: 0.05 - 0.4 mm

💠 Price: ~€2,500-5,000 (depending on configuration)

✅ Advantages

✔️ Large build volume – ideal for industrial applications 🏗️

✔️ Tool changer for multi-color and multi-material printing 🎨

✔️ Improved Auto Bed Leveling for extreme accuracy 🛠️

✔️ Wi-Fi/Ethernet networking – remote control capabilities 📡

✔️ Exceptional quality and reliability for semi-professional use 🚀

❌ Disadvantages

❌ High cost, especially with tool changer configuration

❌ Not widely available yet – requires pre-order

❌ Large size – requires significant workspace

🔥 Special Power

💥 The ultimate Prusa printer for large-scale builds and multi-material printing – bringing industrial quality to your workshop! 🔥🏗️

🖨️ Bambu Lab X1 Carbon

🖨️ Bambu Lab X1 Carbon (English Version)

💠 Type: Desktop 3D Printer

💠 Printing Technology: FDM (Fused Deposition Modeling)

💠 Build Volume: 256 x 256 x 256 mm

💠 Enclosure: Fully enclosed

💠 Frame/Design: High-precision metal frame

💠 Extruder: Direct Drive

💠 Motion System: CoreXY for high-speed and precision

💠 Printing Speed: Very high (>250 mm/s), with accelerations up to 20,000 mm/s²

💠 Auto Bed Leveling: Lidar-based or sensor-controlled Z offset adjustment

💠 Maximum Nozzle Temperature: ~300°C

💠 Maximum Bed Temperature: ~120°C

💠 Heated Bed: Yes

💠 Assembly Required or Pre-Assembled: Ready to use

💠 Screen/Control: Large color touchscreen, mobile app, cloud connectivity

💠 Supported Software: Bambu Studio, Cura, PrusaSlicer

💠 Years on the Market: Released in 2022

💠 Filaments: PLA, PETG, ABS, TPU, Nylon, PA-CF, PC, and more

💠 Layer Resolution: 0.05 - 0.3 mm

💠 Price: ~€1,200-1,500

✅ Advantages

✔️ Extremely fast printing speeds with CoreXY ⚡

✔️ Fully enclosed chamber – great for high-temperature materials like ABS and Nylon 🔥

✔️ Built-in Lidar sensor for advanced Auto Bed Leveling 📡

✔️ AI-based error detection for improved print reliability 🛠️

✔️ Compatible with AMS (Automatic Material System) for multi-color and multi-material printing 🎨

❌ Disadvantages

❌ Higher cost compared to other FDM printers

❌ Limited DIY upgrade potential due to closed ecosystem

❌ Some features require active cloud connectivity

🔥 Special Power

💥 One of the fastest and most advanced 3D printers – perfect for users who want professional-quality prints with full automation! 🚀

🖨️ Bambu Lab P1P

🖨️ Bambu Lab P1P (English Version)

💠 Type: Desktop 3D Printer

💠 Printing Technology: FDM (Fused Deposition Modeling), CoreXY

💠 Build Volume: 256 x 256 x 256 mm (same as X1 Carbon)

💠 Enclosure: Open-frame (customizable with side panels)

💠 Frame/Design: Modular, upgradable structure

💠 Extruder: Direct Drive

💠 Motion System: CoreXY for high-speed and precision

💠 Printing Speed: >200 mm/s (extremely fast, similar to X1 Carbon)

💠 Auto Bed Leveling: Bed position sensor with automatic leveling calculation

💠 Maximum Nozzle Temperature: ~300°C

💠 Maximum Bed Temperature: ~100°C

💠 Heated Bed: Yes

💠 Assembly Required or Pre-Assembled: Ready to use

💠 Screen/Control: Basic color touchscreen, Bambu Studio connectivity

💠 Supported Software: Bambu Studio, Cura, PrusaSlicer

💠 Years on the Market: Released in 2022

💠 Filaments: PLA, PETG, TPU, ABS (with some limitations due to open-frame), and more

💠 Layer Resolution: 0.05 - 0.3 mm

💠 Price: ~€700-900

✅ Advantages

✔️ Highly competitive price for its performance 💰

✔️ Extremely fast printing (>200 mm/s) ⚡

✔️ Modular design – upgradable with DIY panels and mods 🛠️

✔️ Compatible with AMS (Automatic Material System) for multi-color printing 🎨

✔️ Reliable CoreXY system for stable prints 🏗️

❌ Disadvantages

❌ Not fully enclosed – limited ABS/Nylon capabilities

❌ More basic features compared to X1 Carbon (no AI-based monitoring)

❌ No built-in Lidar or advanced auto-calibration

🔥 Special Power

💥 One of the fastest printers in its class, offering incredible value and customizability – perfect for makers who want performance without limits! 🚀

🛠️ Bambu Lab AMS

🛠️ Bambu Lab AMS (Automatic Material System) (English Version)

💠 Type: Automatic Multi-Material / Multi-Color Filament System

💠 Capacity: 4 filament spools (up to 4 AMS units can be linked for 16 spools)

💠 Features:

✔️ Automatic filament switching

✔️ Moisture detection

✔️ Color detection

✔️ Filament tension control

💠 Compatibility: Bambu Lab X1 Series, P1 Series, and possibly future models

💠 Supported Filaments: PLA, PETG, TPU, ABS, PA-CF, etc. (performance may vary with moisture-sensitive materials)

💠 Function: Automatically swaps filaments during printing, enabling full multi-color and multi-material prints

💠 Price: ~€350-500

✅ Advantages

✔️ Enables multi-color and multi-material printing 🎨

✔️ Automatic filament switching without manual intervention 🔄

✔️ Moisture and color detection for optimized printing 🌡️

✔️ Easy setup and integration with Bambu Lab printers 🛠️

❌ Disadvantages

❌ Only compatible with Bambu Lab printers that support AMS

❌ Some filaments (like flexible ones) may have feeding issues

❌ Higher cost compared to manual filament swaps

🔥 Special Power

💥 The Bambu Lab AMS revolutionizes multi-color and multi-material printing – effortless and seamless! 🚀🌈

🖨️ Voron V0 (V0.1 / V0.2)

🖨️ Voron V0 (V0.1 / V0.2) (English Version)

💠 Type: DIY Desktop 3D Printer

💠 Printing Technology: FDM, CoreXY

💠 Build Volume: ~120 × 120 × 120 mm

💠 Enclosure: Fully enclosed

💠 Design: Metal frame with acrylic or polycarbonate panels

💠 Motion System: CoreXY with high-acceleration motion setup

💠 Extruder: Direct Drive "Afterburner" or "Stealthburner" (depending on version)

💠 Auto Bed Leveling: Depends on user assembly and add-ons

💠 Maximum Nozzle Temperature: ~300°C (with proper hotend)

💠 Maximum Bed Temperature: ~120°C

💠 Heated Bed: Yes

💠 Assembly Required or Pre-Assembled: 100% DIY – requires full assembly

💠 Supported Software: Klipper (requires Raspberry Pi)

💠 Years on the Market: Since ~2020 (with continuous upgrades)

💠 Filaments: PLA, PETG, ABS, ASA, TPU, Nylon, and more

💠 Layer Resolution: 0.05 - 0.3 mm

💠 Price: ~€500-800 (depends on components and upgrades)

✅ Advantages

✔️ Ultra-compact – perfect for small spaces or as a secondary printer 🎯

✔️ CoreXY system for fast and precise printing ⚡

✔️ Fully enclosed – ideal for ABS and technical materials 🔥

✔️ Open-source design with strong community support 🛠️

✔️ Extremely sturdy construction for its size 💪

❌ Disadvantages

❌ Requires full assembly – not beginner-friendly 🔩

❌ Limited build volume

❌ Needs Klipper + Raspberry Pi for optimal performance

🔥 Special Power

💥 An ultra-compact yet incredibly fast printer – perfect for hardcore DIYers and those who want a small but powerful machine! 🚀

🖨️ Voron Switchwire

🖨️ Voron Switchwire (English Version)

💠 Type: DIY Desktop 3D Printer

💠 Printing Technology: FDM, bed-slinger (with improved Z-belt system)

💠 Build Volume: ~235 × 235 × 250 mm (depends on components and mods)

💠 Enclosure: Open, but can be enclosed with upgrades

💠 Design: Bed-slinger with Z-belt system instead of traditional lead screws

💠 Extruder: Direct Drive (Afterburner or Stealthburner)

💠 Auto Bed Leveling: Can be upgraded with BLTouch or other sensors

💠 Maximum Nozzle Temperature: ~300°C (with proper hotend)

💠 Maximum Bed Temperature: ~120°C

💠 Heated Bed: Yes

💠 Assembly Required or Pre-Assembled: 100% DIY – requires full assembly

💠 Supported Software: Klipper (requires Raspberry Pi)

💠 Years on the Market: Since ~2021

💠 Filaments: PLA, PETG, TPU, ABS, and more

💠 Layer Resolution: 0.05 - 0.3 mm

💠 Price: ~€600-1,000 (depends on components and upgrades)

✅ Advantages

✔️ Retains Voron-level accuracy but in a familiar bed-slinger design 🎯

✔️ Z-belt system – improves stability and reduces backlash 🏗️

✔️ High print quality and capable of fast speeds ⚡

✔️ Open-source with full customization potential 🛠️

✔️ Easier transition for users coming from Prusa-style printers 🔄

❌ Disadvantages

❌ Requires DIY assembly – not beginner-friendly 🔩

❌ Not as fast as CoreXY Voron models (Voron 2.4, Trident) 🚀

❌ Enclosure requires additional modifications

🔥 Special Power

💥 A bed-slinger printer with Voron DNA – speed, precision, and DIY customization in a well-balanced design! 🚀

🖨️ Voron 1.8

🖨️ Voron 1.8 (English Version)

💠 Type: DIY Desktop 3D Printer

💠 Printing Technology: FDM, CoreXY

💠 Build Volume: 250 × 250 × 250 mm or 300 × 300 × 300 mm (depending on build)

💠 Enclosure: Fully enclosed

💠 Design: Metal frame with acrylic or PC panels

💠 Motion System: CoreXY with stationary bed, printhead moves on X & Y axes

💠 Extruder: Direct Drive (Afterburner or Stealthburner)

💠 Auto Bed Leveling: Supports BLTouch or Inductive Probe add-ons

💠 Maximum Nozzle Temperature: ~300°C (depends on hotend)

💠 Maximum Bed Temperature: ~120°C

💠 Heated Bed: Yes

💠 Assembly Required or Pre-Assembled: 100% DIY – requires full assembly

💠 Supported Software: Klipper (requires Raspberry Pi)

💠 Years on the Market: Since ~2019

💠 Filaments: PLA, PETG, ABS, ASA, Nylon, and more

💠 Layer Resolution: 0.05 - 0.3 mm

💠 Price: ~€800-1,500 (depends on components and upgrades)

✅ Advantages

✔️ Extremely rigid and precise construction for reliable prints 🎯

✔️ Fully enclosed chamber – ideal for ABS, ASA, and Nylon 🔥

✔️ Stationary bed – reduces print failures and improves print uniformity 🏗️

✔️ Less complex than the Voron 2.4, but offers similar print quality ⚡

✔️ Open-source with a strong community support 🛠️

❌ Disadvantages

❌ 100% DIY assembly – requires time and experience 🔩

❌ No Z-belt system like the Voron 2.4, making it slightly slower on the Z-axis

❌ More complex setup compared to commercial 3D printers

🔥 Special Power

💥 A true Voron with durability and precision – perfect for those who want CoreXY without the complexity of the Voron 2.4! 🚀

🖨️ Voron Trident

🖨️ Voron Trident (English Version)

💠 Type: DIY Desktop 3D Printer

💠 Printing Technology: FDM, CoreXY

💠 Build Volume: 250 × 250 × 250 mm, 300 × 300 × 300 mm, 350 × 350 × 350 mm

💠 Enclosure: Fully enclosed

💠 Design: Metal frame, similar to Voron 2.4

💠 Motion System: CoreXY with Triple Independent Z leadscrews instead of belts

💠 Extruder: Direct Drive (Afterburner or Stealthburner)

💠 Auto Bed Leveling: Triple Z leveling – each leadscrew auto-adjusts via Klipper

💠 Maximum Nozzle Temperature: ~300°C

💠 Maximum Bed Temperature: ~120°C

💠 Heated Bed: Yes

💠 Assembly Required or Pre-Assembled: 100% DIY – requires full assembly

💠 Supported Software: Klipper (requires Raspberry Pi)

💠 Years on the Market: Since ~2021

💠 Filaments: PLA, PETG, ABS, ASA, Nylon, PC, PA-CF, and more

💠 Layer Resolution: 0.05 - 0.3 mm

💠 Price: ~€1,000-1,800 (depends on components and upgrades)

✅ Advantages

✔️ Triple Z leveling – automatic bed leveling via firmware 🎯

✔️ Stable CoreXY system – high-speed and precise printing ⚡

✔️ Fully enclosed – ideal for technical materials like ABS, ASA, Nylon 🔥

✔️ Less complex than Voron 2.4 due to leadscrews instead of belts on Z 🏗️

✔️ Strong community support 🛠️

❌ Disadvantages

❌ 100% DIY assembly – requires experience and time 🔩

❌ Slightly slower Z-axis movement compared to Voron 2.4 due to leadscrews

❌ High cost if premium components are chosen

🔥 Special Power

💥 For those who want the stability and large build volume of the Voron 2.4 but prefer leadscrews over belts on Z! 🚀

🖨️ RepRap Huxley

🖨️ RepRap Huxley (English Version)

💠 Type: DIY Desktop 3D Printer (Compact version of Mendel)

💠 Printing Technology: FDM (Fused Deposition Modeling)

💠 Build Volume: ~140 × 140 × 100 mm

💠 Design: Similar to Mendel, but at "half scale" – smaller and more portable

💠 Frame: Combination of threaded rods and printed parts

💠 Extruder: Direct Drive or Bowden (depending on the build)

💠 Auto Bed Leveling: No (original version)

💠 Maximum Nozzle Temperature: ~240°C (depends on hotend)

💠 Maximum Bed Temperature: ~110°C (if heated bed is added)

💠 Heated Bed: No (original version, but upgradeable)

💠 Assembly Required or Pre-Assembled: 100% DIY – requires full assembly and part printing

💠 Supported Software: Marlin (in later versions)

💠 Years on the Market: Since ~2010-2011 (no longer in production)

💠 Filaments: PLA, ABS (with heated bed), PETG, and other basic materials

💠 Layer Resolution: ~0.1 - 0.4 mm

💠 Price: No longer sold – component cost was ~€200-400

✅ Advantages

✔️ Compact and portable – perfect for small spaces and educational use 🎒

✔️ Based on Mendel but smaller and easier to assemble 🏗️

✔️ Low cost – affordable for DIY users 💰

✔️ Open-source and upgradeable 🔄

❌ Disadvantages

❌ Very small build volume – limited for larger projects 📏

❌ Manual bed leveling – no auto bed leveling 🔩

❌ DIY assembly – required 3D printed parts and tuning 🏗️

🔥 Special Power

💥 The smallest RepRap that brought DIY 3D printing to schools, labs, and makers! 🚀

🖨️ MendelMax (2011-2012)

🖨️ MendelMax (2011-2012) (English Version)

💠 Type: DIY Desktop 3D Printer

💠 Printing Technology: FDM (Fused Deposition Modeling)

💠 Build Volume: ~200 × 200 × 200 mm (expandable)

💠 Design: Based on Mendel but using aluminum extrusions instead of threaded rods

💠 Frame: Aluminum extrusions – more rigid and stable than classic Mendel

💠 Extruder: Direct Drive or Bowden (depending on the build)

💠 Auto Bed Leveling: No (original version)

💠 Maximum Nozzle Temperature: ~240°C (depends on hotend)

💠 Maximum Bed Temperature: ~110°C (if heated bed is added)

💠 Heated Bed: No (original version, but upgradeable)

💠 Assembly Required or Pre-Assembled: 100% DIY – requires full assembly and part printing

💠 Supported Software: Marlin (in later versions)

💠 Years on the Market: Since ~2011-2012 (no longer in production)

💠 Filaments: PLA, ABS (with heated bed), PETG, and other basic materials

💠 Layer Resolution: ~0.1 - 0.4 mm

💠 Price: No longer sold – component cost was ~€400-700

✅ Advantages

✔️ More rigid construction – aluminum extrusions provide better stability 🏗️

✔️ Better speeds and fewer vibrations than classic Mendel ⚡

✔️ Expandable design – could be built in larger sizes 📏

✔️ Perfect for DIYers looking for a more “pro” build 🎯

❌ Disadvantages

❌ Requires a custom build – no standard parts or dimensions 🔩

❌ Still a DIY printer – required time and knowledge to assemble 🏗️

❌ No auto bed leveling – required manual bed adjustment 📏

🔥 Special Power

💥 MendelMax revolutionized DIY printer construction – more rigid, faster, and expandable! 🚀

🖨️ RepRap Morgan (Delta-SCARA Hybrid)

🖨️ RepRap Morgan (Delta-SCARA Hybrid) (English Version)

💠 Type: DIY Desktop 3D Printer (with SCARA kinematics)

💠 Printing Technology: FDM (Fused Deposition Modeling)

💠 Build Volume: Medium to large (depends on arm length)

💠 Design: SCARA robotic arm instead of classic X-Y-Z axes, allowing circular print area

💠 Frame: Combination of printed parts and metal rods

💠 Extruder: Direct Drive or Bowden (depending on the build)

💠 Auto Bed Leveling: Depends on user modifications

💠 Maximum Nozzle Temperature: ~240°C (depends on hotend)

💠 Maximum Bed Temperature: ~110°C (if heated bed is added)

💠 Heated Bed: No (original version, but upgradeable)

💠 Assembly Required or Pre-Assembled: 100% DIY – requires full assembly and part printing

💠 Supported Software: Marlin or custom firmware

💠 Years on the Market: Since ~2013

💠 Filaments: PLA, ABS (with heated bed), PETG, and other basic materials

💠 Layer Resolution: ~0.1 - 0.4 mm

💠 Price: No longer sold – component cost was ~€300-600

✅ Advantages

✔️ Innovative design – SCARA arm instead of traditional X-Y-Z 🦾

✔️ Circular print area – unique kinematics compared to cartesian and delta models 🌀

✔️ Open-source and highly customizable – great for experimental users 🎯

✔️ Fewer moving parts – lower wear compared to other designs 🏗️

❌ Disadvantages

❌ Complex setup and tuning – requires experience with alternative kinematics 🛠️

❌ Less community support – not as popular as cartesian or coreXY models 🔄

❌ Originally lacked a heated bed – limited ABS and technical material support 🔥

🔥 Special Power

💥 One of the most unique DIY printers – SCARA kinematics for circular printing and an entirely different approach to 3D printing! 🚀

🖨️ RepRap Kossel (Delta Printer)

🖨️ RepRap Kossel (Delta Printer) (English Version)

💠 Type: DIY Desktop 3D Printer (Delta Kinematics)

💠 Printing Technology: FDM (Fused Deposition Modeling)

💠 Build Volume: Circular base (~170–300 mm diameter) and height ~200–350 mm (depending on tower height)

💠 Design: Triangular Delta setup with 3 towers and arms controlling the hotend

💠 Frame: Aluminum extrusions and printed parts

💠 Extruder: Bowden (to keep moving parts lightweight)

💠 Auto Bed Leveling: Almost essential for proper printing

💠 Maximum Nozzle Temperature: ~260°C (depending on hotend)

💠 Maximum Bed Temperature: ~110°C (if heated bed is added)

💠 Heated Bed: No (original version, but upgradeable)

💠 Assembly Required or Pre-Assembled: 100% DIY – requires assembly and calibration

💠 Supported Software: Marlin, Repetier, Klipper

💠 Years on the Market: Since ~2012-2013

💠 Filaments: PLA, ABS (with heated bed), PETG, TPU, and other basic materials

💠 Layer Resolution: ~0.05 - 0.3 mm

💠 Price: No longer sold – component cost was ~€300-700

✅ Advantages

✔️ Extremely fast printing – Delta kinematics allow high-speed movements ⚡

✔️ Smooth motion – ideal for round objects and curved surfaces 🌀

✔️ Lighter moving parts – better stability at high speeds 🏗️

✔️ Open-frame design – easy access and maintenance 🛠️

✔️ One of the first and most famous Delta designs 🎯

❌ Disadvantages

❌ Complex calibration – requires precise setup and auto bed leveling 🔧

❌ Bowden extruder – difficult to print flexible materials (TPU) due to filament distance 🏗️

❌ Circular build volume – may not be ideal for rectangular objects 📏

❌ Limited support – smaller community compared to CoreXY or Cartesian printers 🌍

🔥 Special Power

💥 One of the fastest DIY 3D printers – perfect for smooth & high-speed prints! 🚀

RepRap Wilson Series

🖨️ RepRap Wilson Series (English Version)

💠 Type: DIY Desktop 3D Printer (Cartesian)

💠 Printing Technology: FDM (Fused Deposition Modeling)

💠 Build Volume: ~200 × 200 × 200 mm (depends on the version)

💠 Design: Similar to Prusa i3 but with aluminum extrusions for the main frame and printed connectors

💠 Frame: Aluminum extrusions + 3D printed parts

💠 Extruder: Direct Drive or Bowden (depending on the build)

💠 Auto Bed Leveling: Available in some versions (Wilson II & other re-mixes)

💠 Maximum Nozzle Temperature: ~260°C (depends on hotend)

💠 Maximum Bed Temperature: ~110°C (if heated bed is added)

💠 Heated Bed: Available in most versions

💠 Assembly Required or Pre-Assembled: 100% DIY – requires full assembly and printed parts

💠 Supported Software: Marlin, Repetier

💠 Years on the Market: Since ~2014

💠 Filaments: PLA, ABS (with heated bed), PETG, TPU, and other basic materials

💠 Layer Resolution: ~0.05 - 0.3 mm

💠 Price: No longer sold – component cost was ~€300-600

✅ Advantages

✔️ Improved design over Prusa i3 – aluminum extrusions instead of CNC-cut plates 🏗️

✔️ Easier assembly – fewer screws and better access to components 🔩

✔️ Supports auto bed leveling – more beginner-friendly ⚡

✔️ Open-source design – strong community and variations (Wilson II, re-mixes) 🛠️

❌ Disadvantages

❌ Less rigid than modern Cartesian printers 🏗️

❌ Not sold pre-assembled – requires DIY assembly and printed parts 🔧

❌ Now outdated by Prusa MK3 and newer models 📏

🔥 Special Power

💥 One of the most accessible and improved DIY Cartesian printers – a great open-source choice for makers! 🚀

3D Printing

⚠️ Disclaimer ⚠️

🛑 Important Notice! 🛑

The following information about each print is indicative only 📌 and has been gathered from various online sources 🌐. It is solely intended for the purpose of this game 🎮.

❌ These are not official specifications

❌ This is not a guide for printing processes or object preparation

✅ Before You Print Anything:

🔎 Search for the object you want, download it, and place it in your preferred slicer 🖥️

⚙️ Adjust the printing parameters (temperatures, speeds, layer height, etc.) according to your needs 🛠️

📏 Keep in mind that requirements may vary depending on the quality and size you aim for 🎯

You control the settings and choices in the real world outside this game. The information provided here is for entertainment purposes only and is based on general, indicative data. 🚀

🖨️ Phone Stand

🖨️ Phone Stand

💠 Type: Mechanical print (fixed or foldable stand)

💠 Printing Technology: FDM (Fused Deposition Modeling)

💠 Print Volume: ~100 × 100 × 100 mm (depending on the design)

💠 Design: Simple structure with no complex mechanisms, either single-piece or assembled

💠 Colors: Dual-color (or single-color if using one filament)

💠 Weight: ~50g

💠 Accuracy: Medium (0.2mm - 0.3mm layer height)

💠 Materials: PLA (easy printing), PETG (heat resistance), ABS (for extra durability)

💠 Infill: 15-25% (depends on desired strength)

💠 Nozzle Size: 0.4mm (standard) or 0.6mm (for faster printing)

💠 Print Time: 2-5 hours (depending on model and settings)

✅ Advantages

✔️ Simple construction – can be printed by anyone with any 3D printer 🛠️

✔️ Useful gadget – perfect for a desk, kitchen, gaming setup, or even a car 🚗

✔️ Low material cost – uses minimal filament (~10-20g PLA) 💰

✔️ Easy customization – can add logos or personal text ✨

✔️ Foldable option – great for portability and on-the-go use 🎒

⚠️ Challenges

❌ Small surface contact with the table – may detach if no brim or raft is used 🛑

❌ Requires good bed adhesion – especially for ABS and PETG 🔥

❌ Dual-color prints require a Dual Extruder or manual filament swap 🎨

❌ Some designs may need supports for angled surfaces 🏗️

🔥 Special Power

💥 An awesome gadget to keep your phone standing upright! 📱🔥

🏡 Wall or Door Hooks

🏡 Wall or Door Hooks

💠 Type: Functional component for organization and storage

💠 Printing Technology: FDM (Fused Deposition Modeling)

💠 Print Volume: ~50 × 50 × 100 mm (depending on design and usage)

💠 Design: Simple or decorative, attachable to a wall or door using screws or adhesive tape

💠 Colors: Customizable to match the room's aesthetic

💠 Weight: ~10-30g (depending on size and density)

💠 Accuracy: Medium (0.2mm - 0.3mm layer height)

💠 Materials:

✔️ PLA (for lightweight objects)

✔️ PETG (for moisture resistance)

✔️ ABS (for high strength and temperature resistance)

💠 Infill: 30-50% (depending on the weight of the items it will hold)

💠 Nozzle Size: 0.4mm (standard)

💠 Print Time: 1-3 hours (depending on size and settings)

✅ Advantages

✔️ Customization: Can be designed in various shapes and colors to fit different spaces.

✔️ Easy Printing: Simple designs that do not require supports, making printing fast and efficient.

✔️ Space Organization: Helps keep items tidy, saving space and maintaining order.

⚠️ Challenges

❌ Strength: Choosing the right material and infill is crucial for supporting heavier objects.

❌ Mounting: Proper installation (using screws or strong adhesive tape) is necessary for stability.

❌ Environmental Conditions: In humid or high-temperature areas, PETG or ABS should be used instead of PLA.

🔥 Special Power

💥 Customizable hooks that combine functionality with style, making your space more organized! 🏡🔩

🔑 Key Organizer

🔑 Key Organizer

💠 Type: Functional accessory for key organization and portability

💠 Printing Technology: FDM (Fused Deposition Modeling)

💠 Print Volume: ~80 × 20 × 20 mm (depending on the design)

💠 Design: Compact and ergonomic, customizable for different key sizes

💠 Colors: Customizable based on personal preference

💠 Weight: ~15-30g (depending on material and density)

💠 Accuracy: High (0.1mm - 0.2mm layer height)

💠 Materials:

- PLA: Easy to print, suitable for everyday use

- PETG: Moisture-resistant and more flexible

- ABS: High durability and strength

💠 Infill: 30-50% (for a balance of strength and weight)

💠 Nozzle Size: 0.4mm (standard)

💠 Print Time: 1-2 hours (depending on design and settings)

✅ Advantages

✔️ Customization: Print a key organizer that perfectly fits your keys

✔️ Sleek design: Choose designs that match your personal style

✔️ Cost-effective: Printing cost is approximately €0.80, much cheaper than buying a pre-made product

⚠️ Challenges

❌ Durability: Choosing the right material is crucial for long-term use

❌ Assembly: Some designs may require additional parts such as screws or nuts

❌ Precision printing: High accuracy is needed to ensure a perfect fit for the keys

🔥 Special Power

💥 A unique, customizable key organizer that blends functionality with personal style! 🔑✨

🔲 Cotton Swab / Toothpick Holder

🔲 Cotton Swab / Toothpick Holder

💠 Type: Home organizer for storing cotton swabs or toothpicks

💠 Printing Technology: FDM (Fused Deposition Modeling)

💠 Print Volume: ~60 × 60 × 100 mm (depending on design)

💠 Design: Sleek and functional, with a lid or dispensing mechanism

💠 Colors: Customizable based on personal preference

💠 Weight: ~30-50g (depending on material and density)

💠 Accuracy: High (0.1mm - 0.2mm layer height)

💠 Materials:

- PLA: Easy to print, suitable for everyday use

- PETG: Moisture-resistant and flexible

- ABS: High durability and long-lasting

💠 Infill: 20-30% (for a balance of strength and weight)

💠 Nozzle Size: 0.4mm (standard)

💠 Print Time: 2-3 hours (depending on design and settings)

✅ Benefits

✔️ Customization: Choose the design, color, and size that fits your space

✔️ Organization: Keeps cotton swabs or toothpicks neatly stored and easily accessible

✔️ Cost-effective: Printing cost is approximately €0.70, cheaper than buying a ready-made product

⚠️ Challenges

❌ Durability: Choosing the right material is essential for long-term use

❌ Assembly: Some designs may require additional components or mechanisms

❌ Precision Printing: High accuracy is needed to ensure a proper fit for the parts

🔥 Special Power

💥 A unique, customizable holder that combines functionality with personal style! 🛁✨

🔌 Cable Organizer

🔌 Cable Organizer

💠 Type: Accessory for organizing and managing cables

💠 Printing Technology: FDM (Fused Deposition Modeling)

💠 Print Volume: ~50 × 50 × 20 mm (depending on design)

💠 Design: Simple and functional, with slots or grooves for holding cables

💠 Colors: Customizable based on personal preference

💠 Weight: ~10-20g (depending on material and density)

💠 Accuracy: High (0.1mm - 0.2mm layer height)

💠 Materials:

- PLA: Easy to print, suitable for everyday use

- PETG: Moisture-resistant and more flexible

- ABS: High durability and long-lasting

💠 Infill: 20-30% (for a balance of strength and weight)

💠 Nozzle Size: 0.4mm (standard)

💠 Print Time: 1-2 hours (depending on design and settings)

✅ Benefits

✔️ Customization: Choose the design, color, and size that fits your needs

✔️ Organization: Keeps cables tidy and prevents tangling

✔️ Cost-effective: Printing cost is approximately €0.50, cheaper than buying a ready-made product

⚠️ Challenges

❌ Durability: Choosing the right material is crucial for long-term use

❌ Compatibility: Ensure the design fits your cables and space

❌ Precision Printing: High accuracy is needed for a perfect cable fit

🔥 Special Power

💥 A customizable cable organizer that keeps your space neat and clutter-free! 🧩

🧻 Toilet Paper or Kitchen Towel Holder

🧻 Toilet Paper or Kitchen Towel Holder

💠 Type: Organizational accessory for the bathroom or kitchen, designed to hold toilet paper or kitchen towel rolls.

💠 Printing Technology: FDM (Fused Deposition Modeling)

💠 Print Volume: ~150 × 150 × 50 mm (depending on the design)

💠 Design: Functional and durable, adjustable for various roll sizes.

💠 Colors: Customizable based on personal preference.

💠 Weight: ~50-100g (depending on material and density)

💠 Accuracy: Medium to high (0.2mm - 0.3mm layer height)

💠 Materials:

- PLA: Easy to print, suitable for low-humidity areas.

- PETG: Moisture-resistant, ideal for bathrooms or kitchens.

- ABS: High durability, but requires an enclosed chamber for printing.

💠 Infill: 30-50% (for increased strength)

💠 Nozzle Size: 0.4mm (standard)

💠 Print Time: 3-5 hours (depending on design and settings)

✅ Benefits

✔️ Customization: Choose the design, color, and size that fits your space.

✔️ Cost-effective: Printing cost is approximately €1.50, significantly cheaper than buying a ready-made product.

✔️ Convenience: Ability to print replacements or modifications at any time.

⚠️ Challenges

❌ Durability: Choosing the right material is crucial for long-term use, especially in humid environments.

❌ Stability: Ensure the holder is properly mounted to support the roll’s weight.

❌ Precision Printing: Careful calibration is needed to ensure proper fit and functionality.

🔥 Special Power

💥 A stylish and customizable holder that adds both functionality and design to your space, keeping toilet paper or kitchen towels always within reach! 🧩✨

🕰️ Wall Clock (Custom Design)

🕰️ Wall Clock (Custom Design)

💠 Type: Decorative and functional wall clock with a unique, personalized design.

💠 Printing Technology: FDM (Fused Deposition Modeling)

💠 Print Volume: ~200 × 200 × 20 mm (depends on the design)

💠 Design: Customizable, with options for patterns, numbers, hands, and colors to match your personal style.

💠 Colors: Fully customizable according to your preferences.

💠 Weight: ~100-200g (depending on material and density)

💠 Accuracy: High (0.1mm - 0.2mm layer height)

💠 Materials:

- PLA: Easy to print, available in a variety of colors, suitable for indoor use.

- PETG: More durable and moisture-resistant, ideal for kitchens or bathrooms.

- ABS: High strength and durability, but requires an enclosed chamber for printing.

💠 Infill: 15-25% (for a balance of strength and weight)

💠 Nozzle Size: 0.4mm (standard)

💠 Print Time: 6-10 hours (depending on design complexity and settings)

✅ Benefits

✔️ Personal Touch: Create a clock that reflects your style and fits perfectly in your space.

✔️ Cost-Effective: Printing cost is approximately €5-7 (excluding the clock mechanism), much cheaper than buying a pre-made clock.

✔️ Creativity: An opportunity to experiment with different designs, materials, and colors.

⚠️ Challenges

❌ Clock Mechanism Required: You will need to purchase a clock mechanism separately and integrate it into the printed design.

❌ Assembly Precision: Proper placement of the mechanism and hands is necessary for smooth operation.

❌ Material Durability: Choose the right material based on room conditions (e.g., humidity, temperature) to ensure long-term durability.

🔥 Special Power

💥 A unique, customizable wall clock that blends functionality with personal style, bringing character and vibrancy to your space! 🕰️✨

🚪 Door Stopper

🚪 Door Stopper

💠 Type: An accessory designed to keep doors in place, preventing them from closing or opening due to air currents.

💠 Printing Technology: FDM (Fused Deposition Modeling)

💠 Print Volume: ~60 × 30 × 40 mm (depending on the design)

💠 Design: Simple and functional, with an angled or specially shaped structure for a secure grip under the door.

💠 Colors: Customizable based on personal preference.

💠 Weight: ~20-40g (depending on material and density)

💠 Accuracy: Medium (0.2mm - 0.3mm layer height)

💠 Materials:

- PLA: Easy to print, suitable for indoor use.

- PETG: More durable and heat-resistant, ideal for warmer environments.

- ABS: High durability and strength but requires an enclosed chamber for printing.

💠 Infill: 50-100% (for increased durability and weight)

💠 Nozzle Size: 0.4mm (standard)

💠 Print Time: 1-2 hours (depending on design and settings)

✅ Benefits

✔️ Cost-Effective: Printing cost is approximately €0.70, much cheaper than buying a pre-made product.

✔️ Customization: Adjust the height and design to perfectly fit your door and room decor.

✔️ Convenience: Quick to print and ready for immediate use, with the option to print multiple units for different doors.

⚠️ Challenges

❌ Durability: Choosing the right material is essential to withstand pressure and wear from frequent use.

❌ Stability: Requires sufficient weight or anti-slip material to prevent movement.

❌ Precision Printing: Careful calibration is needed to ensure a proper fit and optimal functionality.

🔥 Special Power

💥 A customizable and budget-friendly door stopper that keeps your doors exactly where you want them while adding a personal touch to your space! 🚪✨

☕ Coasters for Glasses

☕ Coasters for Glasses

💠 Type: Small, flat objects placed under cups or glasses to protect surfaces from heat, moisture, or stains.

💠 Printing Technology: FDM (Fused Deposition Modeling)

💠 Print Volume: ~100 × 100 × 5 mm (per coaster)

💠 Design: Customizable, with options for shape (round, square, hexagonal), pattern, and color to match your decor.

💠 Colors: Fully customizable based on personal preference.

💠 Weight: ~15-25g (depending on material and density)

💠 Accuracy: High (0.1mm - 0.2mm layer height)

💠 Materials:

- PLA: Easy to print, available in various colors, ideal for indoor use.

- PETG: More durable and moisture-resistant, great for humid environments.

- ABS: High strength and durability but requires an enclosed chamber for printing.

💠 Infill: 20-30% (for a balance between strength and weight)

💠 Nozzle Size: 0.4mm (standard)

💠 Print Time: 1-2 hours per coaster (depending on design complexity and settings)

✅ Benefits

✔️ Personalized Design: Create coasters that reflect your style and perfectly match your space.

✔️ Cost-Effective: Printing cost is approximately €1 for a set of 4, much cheaper than buying pre-made ones.

✔️ Creative Freedom: Experiment with different designs, materials, and colors.

⚠️ Challenges

❌ Heat Resistance: Choose the right material to withstand hot beverages.

❌ Slipping: Consider adding a non-slip base or using materials with good grip to prevent sliding.

❌ Maintenance: Select materials that are easy to clean and do not absorb stains.

🔥 Special Power

💥 Stylish and customizable coasters that protect your surfaces while adding a personal touch to your decor! ☕✨

🖥️ Headphone Stand

🖥️ Headphone Stand

💠 Type: A stand designed for organizing and storing headphones, keeping your desk tidy and protecting your headphones from damage.

💠 Printing Technology: FDM (Fused Deposition Modeling)

💠 Print Volume: ~100 × 100 × 200 mm (depending on the design)

💠 Design: Customizable, with adjustable height, shape, and color to match your desk and headphones.

💠 Colors: Fully customizable based on personal preference.

💠 Weight: ~150-250g (depending on material and density)

💠 Accuracy: High (0.1mm - 0.2mm layer height)

💠 Materials:

- PLA: Easy to print, available in various colors, suitable for indoor use.

- PETG: More durable and moisture-resistant, ideal for humid environments.

- ABS: High strength and durability but requires an enclosed chamber for printing.

💠 Infill: 30-50% (for a balance between strength and weight)

💠 Nozzle Size: 0.4mm (standard)

💠 Print Time: 6-10 hours (depending on design complexity and settings)

✅ Benefits

✔️ Customization: Create a stand that perfectly matches your desk and headphones by choosing your preferred design, color, and size.

✔️ Cost-Effective: Printing cost is approximately €2, much cheaper than buying a pre-made product.

✔️ Organization: Keeps your headphones in a safe place, preventing damage and saving desk space.

⚠️ Challenges

❌ Stability: Ensure the base has enough weight or a non-slip surface to remain stable during use.

❌ Durability: Choose a material strong enough to support the weight of your headphones without bending.

❌ Compatibility: Design or select a model that fits the size and shape of your headphones.

🔥 Special Power

💥 A customizable and stylish stand that keeps your headphones organized and protected while adding a touch of elegance to your desk! 🖥️🎧✨

🏠 Clothing or Belt Hanger for Wardrobes

🏠 Clothing or Belt Hanger for Wardrobes

💠 Type: An organizational accessory for wardrobes, designed for storing and arranging clothes, belts, or other accessories.

💠 Printing Technology: FDM (Fused Deposition Modeling)

💠 Print Volume: ~150 × 50 × 100 mm (depending on the design)

💠 Design: Customizable, with options for the number of hooks, spacing, and overall dimensions to fit your needs and available wardrobe space.

💠 Colors: Customizable based on personal preference.

💠 Weight: ~50-100g (depending on material and density)

💠 Accuracy: Medium to high (0.2mm - 0.3mm layer height)

💠 Materials:

- PLA: Easy to print, suitable for indoor use.

- PETG: More durable and moisture-resistant, ideal for humid environments.

- ABS: High durability and strength but requires an enclosed chamber for printing.

💠 Infill: 30-50% (for increased strength and longevity)

💠 Nozzle Size: 0.4mm (standard)

💠 Print Time: 3-5 hours (depending on design complexity and settings)

✅ Benefits

✔️ Custom Fit: Adjust the size, number of hooks, and design to perfectly suit your wardrobe.

✔️ Cost-Effective: Printing cost is approximately €1-1.50, much cheaper than buying a pre-made product.

✔️ Efficient Organization: Keeps clothes, belts, and accessories neatly arranged and easy to access.

⚠️ Challenges

❌ Weight Capacity: Choosing the right material and infill is crucial for supporting heavier items.

❌ Mounting Stability: Ensure proper attachment to the wardrobe for secure placement.

❌ Print Accuracy: Precise printing is needed to ensure hooks fit correctly and function well.

🔥 Special Power

💥 A customizable and stylish wardrobe hanger that helps you stay organized while adding a personal touch to your space! 👗✨

🚲 Wall-Mounted Bicycle Holder

🚲 Wall-Mounted Bicycle Holder

💠 Type: A wall-mounted support designed for bicycle storage, saving space and keeping your bike secure.

💠 Printing Technology: FDM (Fused Deposition Modeling)

💠 Print Volume: ~200 × 150 × 100 mm (depending on the design)

💠 Design: Customizable, with adjustable sizing to fit different types and sizes of bicycles, ensuring stable and secure support.

💠 Colors: Fully customizable based on personal preference.

💠 Weight: ~300-500g (depending on material and density)

💠 Accuracy: Medium to high (0.2mm - 0.3mm layer height)

💠 Materials:

- PETG: Provides durability and moisture resistance, ideal for environments with changing conditions.

- ABS: High strength and impact resistance, but requires an enclosed chamber for printing.

- PLA: Suitable for indoor use but less resistant to heavy loads and extreme temperatures.

💠 Infill: 50-100% (for maximum strength and stability)

💠 Nozzle Size: 0.4mm (standard)

💠 Print Time: 8-12 hours (depending on design complexity and settings)

✅ Benefits

✔️ Space-Saving: Allows you to store your bike securely on the wall, freeing up floor space.

✔️ Customization: Adjust the design to perfectly fit your bicycle’s size and weight.

✔️ Cost-Effective: Printing cost is approximately €5-7, much cheaper than buying a pre-made product.

⚠️ Challenges

❌ Weight Support: Choosing the right material and infill percentage is crucial to ensure the holder can support the bicycle’s weight.

❌ Mounting Stability: Proper wall mounting with strong anchors or screws is essential for safety.

❌ Print Durability: Requires high-quality filament and precise settings to ensure long-lasting performance.

🔥 Special Power

💥 A sturdy and customizable wall-mounted bike holder that keeps your bicycle secure while maximizing your space! 🚲🔩✨

📷 Camera / GoPro Mount

📷 Camera / GoPro Mount

💠 Type: A mount designed to securely hold cameras or GoPro devices, allowing for versatile positioning and stable footage capture.

💠 Printing Technology: FDM (Fused Deposition Modeling)

💠 Print Volume: Approximately 50 × 50 × 100 mm (depending on the design)

💠 Design: Customizable to fit various camera models and mounting scenarios, ensuring a secure and tailored fit.

💠 Colors: Fully customizable based on personal preference.